‘Top down’ and from operational practice to more sustainable management

Everyone wants to operate more sustainably, but what does that mean in practice? The aim can be to reduce a site's energy consumption or to reduce waste. This can be collected by type for recycling, or a company can prioritise certain ISO certifications. Here are several examples of how this can be done. Visitors will find even more at Ilmac 2025 in Basel.

Everyone wants to operate more sustainably, but what does that mean in practice? The aim can be to reduce a site’s energy consumption or to reduce waste. This can be collected by type for recycling, or a company can prioritise certain ISO certifications. Here are several examples of how this can be done. Visitors will find even more at Ilmac 2025 in Basel.

Starting point: Standards

Company A takes a top-down approach based on the ISO standards numbered 14.001 and 50.001. According to the first of these standards, an initially abstract procedure is defined, a cycle from the definition of environmental objectives to their realisation and monitoring through to the development of suggestions for improvement. ISO 50.001, with its more comprehensive list of mandatory and documented information, is more specific. This includes, for example, energy planning, energy output levels and energy performance indicators. To give you a rough idea, ISO 14.001 is suitable for small and medium-sized companies and ISO 15.001 for large ones, but it depends on the individual case.

Implementation in operational measures

Company B is deeper in the change process. Concrete proposals and instructions for action are on the table. Internal working groups have specified switching the lighting at entire sites to LEDs as a target-oriented measure. Solar panels are to be installed on the roofs and walls. In future, heat is to be recovered from the many compressors in production, liquid waste is to be evaporated and fleet logistics are to be trimmed to fewer individual journeys.

Starting point: operational practice

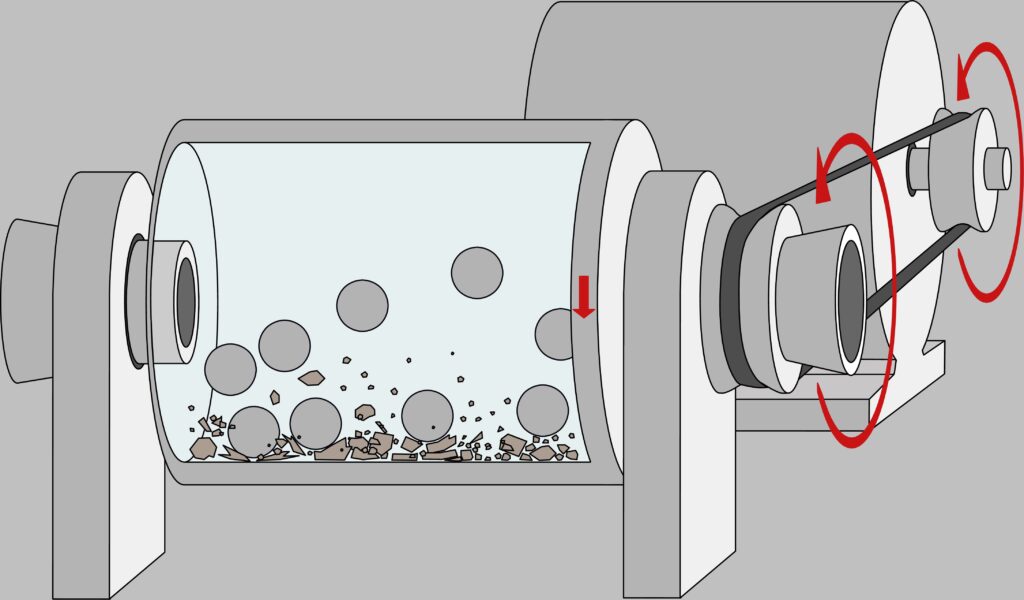

Company C starts directly with operational practice and has purchased a new ball mill for its pharmaceutical production in order to benefit from the advantages of mechanochemistry. The reactants collide with grinding media and are thus activated. The reaction to form the active ingredient takes place without solvents, with high energy efficiency and CO2 savings compared to conventional processes.

From mechanochemistry to photochemistry: Today, versatile catalysts can convert low-energy light into high-energy light and thus initiate reactions and keep them going. What is new is that it can also be done without precious metals and rare earths and instead with molybdenum, for example. This finally makes the more sustainable catalysis process cost-effective.

Magnetic fields, in turn, can be used to calm the flows in liquid-carrying pipes, avoid energy-guzzling turbulence and maintain laminar flows. Globally, the energy-saving potential of this application of magnetochemistry is up to 10 per cent.

Electrochemistry is currently at the top of the sustainability rankings – especially due to the importance of lithium-metal batteries for carbon-neutral mobility in the future. However, these batteries themselves have a huge CO2 footprint. This could potentially be drastically reduced with a process developed by ETH Zurich that reduces the amount of fluorine in the electrolyte to a twentieth.

The Ilmac industry event in Basel gives its visitors a clear orientation when it comes to sustainability. Over three days, exhibitors present what is technically possible today and advise companies on how best to approach this important topic for the future. The Ilmac Conference will provide more in-depth information. An attractive programme in cooperation with the Swiss Chemical Society will address the topic of ‘sustainability’ in several top-class keynotes. Interested exhibiting companies can take part in the Ilmac Preview Event on 3 April 2025 at Syngenta in Basel.