“Artificial intelligence – tangible benefits, especially in combination with automation and digitalization

Faster to the active ingredient or analysis result with AI

Artificial intelligence (AI) is neither artificial nor intelligent, but it is extremely useful in the development of active ingredients, in materials research and, above all, in the evaluation of a wide range of image information. The Ilmac 2025 industry event in Basel will show how these opportunities can be implemented in the day-to-day operations of a chemical, pharmaceutical or biotech company.

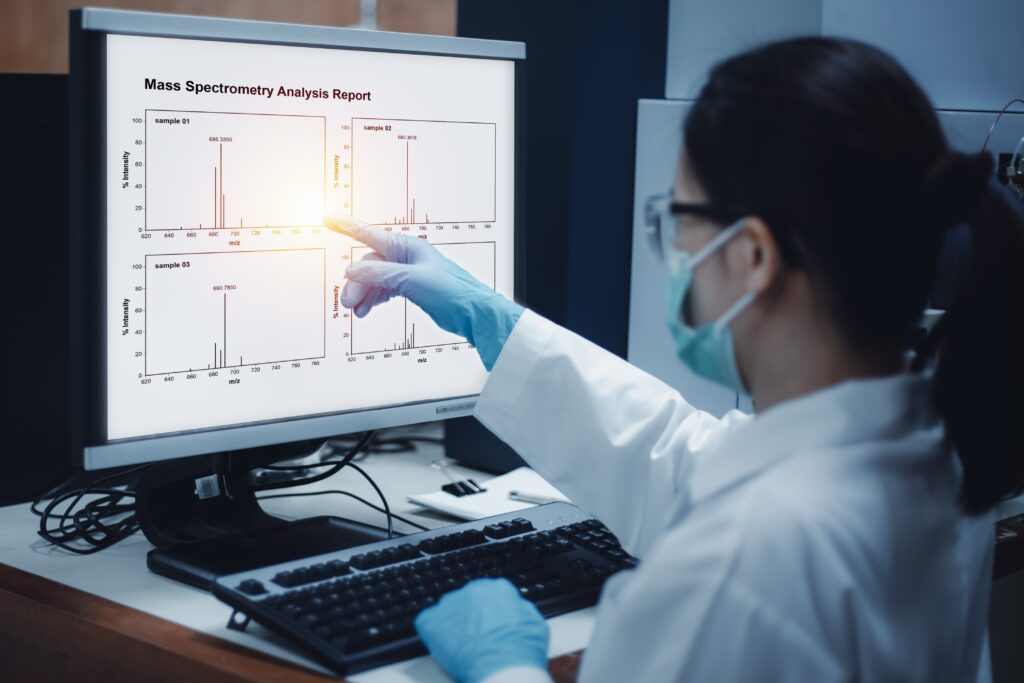

Artificial intelligence provides effective support for doctors and chemists when evaluating X-ray and MRI images (e.g. mammography), infrared and mass spectra. This allows cancer and other diseases to be detected more quickly and treated with a higher probability of success. It also speeds up the process from analysis results in raw data to evaluation. Even unknown substances can be identified with AI support.

Another typical area of application relates to drug research: based on known substances, AI suggests promising candidates. These can, for example, be more effective, better tolerated or easier to apply.

Similarly, materials research can create materials with desired properties in silico. These could be 3D printable plastics with specific strengths and colors, for example.

AI can also be useful in the control of chemical, pharmaceutical and biotech processes. For example, temperature and pressure curves have certain characteristics over certain periods of time. Artificial intelligence can check such patterns: Is the process moving in smooth waters, or are anomalies occurring? In the latter case, it may be necessary to intervene.

A high degree of automation and digitalization pays off in many ways here. This is because AI requires a lot of measured values in the form of digital data as input. These can be temperatures, pressures, colorations of liquids, vibrations of compressors, axial acceleration measurements of motors and much more. With AI support, this sensory information can be used to implement energy-efficient fine control and predictive maintenance.

However, AI is generally not a “plug-and-play tool”. The data acquisition system required for this includes machines with programmable logic controllers (PLCs) and sensors connected to them. It also includes a gateway, i.e. a network node for data transmission, and a temporary memory for fast data retrieval (cache). In addition, data security must be guaranteed, especially with an internet connection for the use of IoT tools (“Internet of Things”).

In all applications, artificial intelligence is not artificial because it is first and foremost trained by humans. The doctor tells the artificial intelligence whether he recognizes a tumour on an X-ray image; the analyst says whether the CO2 band is visible in the IR spectrum; drug and material developers provide successful drugs or materials as training input. The AI fed with many X-ray images, active ingredients, materials or spectra then performs many tasks more reliably than humans.

This holds enormous opportunities for the use of AI in operational practice, especially in combination with automation and digitalization. They will become tangible in their full range at this year’s Ilmac Basel. This topic will be explored in greater depth at the conference on 16.09.2025 and at the Future of Life Sciences Area.